|

|

Latest

News Home Contents

Site Map

David Bradburn's Build Progress

| I

took the engine to the factory when I collected the chassis and

they fitted it. 5th.October 1999. The photo is rolling it out onto

flat-bed trailer for transport home. |

I purchased a rolling chassis ready for a Rover 3.5l V8

engine.

Engine purchased from RPI in Norfolk August 1999. It is ex

military and had been prepared by them for road use.

The heads have

been upgraded to 4.6 valves and made for unleaded fuel. The

compression ratio raised from 8.2 to 9.8. Its output should be a

little under 200bhp. It came painted with a yucky

military preservative green. It is now red and blue, and the

aluminium rocker-box covers and SU carb units I have polished.

|

| November

1999 with some parts clamped and temporarily fitted |

|

|

May 2000: 6 months into the build. Much of the bodywork

fitted, but lots of finishing of panels and gaps to do. I cannot

do the near-side door until I turn the car round!

|

|

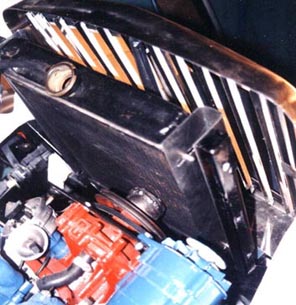

The V8 engine is just about as big as can be put under the

bonnet.

The Radiator (ex FX4 taxi) has to be about an inch forward of

normal, which makes the bonnet metalwork as long as it possibly

can be. The fan (ex Cavalier) is mounted between the grille and

the rad.

The water-pump nuts have been changed for rebated

cap-screws to gain about ¼ inch. This leaves about ¼ inch

clearance each side of the radiator.

|

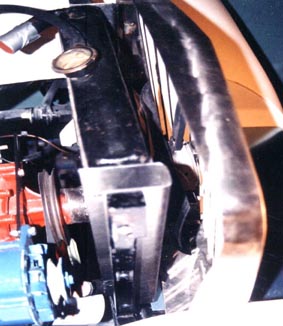

| The alternator would have been

outside the bonnet, so it had to move forward 3/8 inch to clear

the rocker-box and fold in close to the engine. This involved

moving the water-pump pulley and crank shaft pulley 3/8 inch

forward also. Crank pulley easy with made-up plate. |

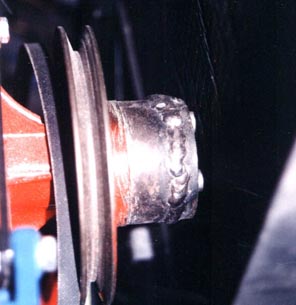

| Detail

of shortened pulley shaft.

Water pump

much more difficult. With considerable help from an engineer

friend we took the pulley, which is an iron casting that includes

a tubular shaft and slots over the water-pump bearing, cut 3/8

inch out of the shaft and welded it up.

|

|

|

Complete

view with alternator |

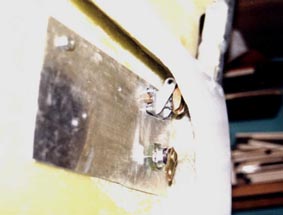

| JBA informed me Jaguar-type handles were now available for

the car from S&J Motors and I plumped for those, having been

assured by the supplier that they would not be an SVA problem.

The

next sequence of photos is fitting the handle and aluminium

backing plate. This one is the basic hole cut into the door

|

|

|

The handle fitted into place |

| The door with the supplied hand recess cut off |

|

|

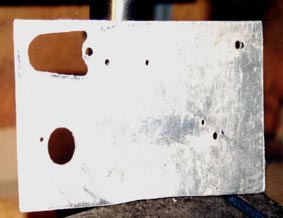

The reinforcing plate (scrap aluminium 1/8 inch thick)

ready to fit |

| Handle and plate fitted: outside |

|

|

The plate will be fibre-glassed in due

course.

|

E-Mail

David

More from David later.

Photos Courtesy of David Bradburn.

|

J

B

A |