|

Engine Rebuild

After I had fitted the brake piping and

hydraulic

hoses to the chassis as far as I could without the body tub, I turned my

attention to the engine. Although it had been cleaned as previously

described, it took a lot of work on the bench with cloths, brushes,

(including a handy toothbrush), and scrapers, to get it really clean.

I then completely dismantled it and inspected it carefully.

|

The cylinder bores were smooth but

were also showing signs of wear. As the valve spindles in the

Pinto engine slide in the cast iron of the block , they were also

showing wear. This model and year, however, was fitted with valve

seating inserts so the engine will be OK with unleaded fuel.

|

|

As the donor car had done 90,000 miles, I

was not surprised to find some wear in the camshaft centre bearing. The

cams had also worn to the point that the case hardening was nearly

through in places.

|

|

|

|

As I was

spending a lot of time effort and money on the whole project.

I decided

to have the engine refurbished by a local engine specialist as follows:- |

| New camshaft, bearings, followers, and

seals

|

|

|

|

Cylinder rebore, new pistons, and gudgeon pins.---Crankshaft polished, new

seals.--Valve spindle sleeves.--Cylinder head and block ground.

|

| Once I

had this done I re-assembled the engine and painted it as I went along.

|

|

|

The gearbox is too complicated for non- professional strip and re-build,

so I'm hoping for the best and have just cleaned and painted it. Before

assembling it to the engine however I fitted a new clutch plate.

|

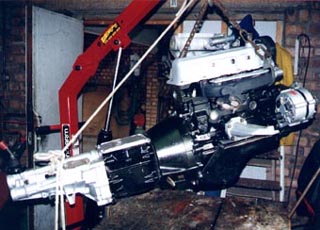

| Once

the assembly was complete we managed to sling the engine on our engine

crane so that it went in over the chassis fairly easily.

|

|

|

|

We had drilled

out the rivets that held the gearbox bracket to the formed sierra

mounting and we attached this to the gear box before clamping it in

place temporarily (over) the chassis mounting plates.

|

| The engine and

gearbox assembly was then moved sufficiently to allow the mounting bolt

holes to be drilled through the bracket using it as a template.

It is only the centre part of the sierra gearbox

mounting plate that is used.

|

|

The

bracket was then bolted in place (under) the mounting plates before the

complete assembly including engine, gearbox, and drive shaft, was

finally bolted down.

| The Engine finally in place. |

|

Fitting the CBU is next.

|