|

J

B

A

J

A

V

E

L

I

N |

Latest

News Home Contents Site Map

Alex

Sargent's

JBA Javelin Restoration

|

Photo courtesy of Dave Tennant.

|

Alex's Javelin fondly known as No1. Shown here on

the JBA stand at a show when it was the JBA factory demonstrator.

Dave Tennant took this photo, whilst visiting

the venue in Leeds.

|

Alex bought the Javelin in the middle of

2000.

Read his own account of his restoration project.

|

|

I used the Javelin until the end of the

season, but now it was time to strip the car down for a complete

refurbishment.

The first job was to remove the Ford 2 litre

engine. then all the ancillaries. |

| The Engine bay was in a bad way with

rust and needed hours of restoration work and welding to return it

to pristine condition. |

|

|

|

Once all the repairs

had been done to the inner wings, It was time to protect all my

work.

Firstly the

engine bay is treated to a coat of zinc primer. Then a coat of

standard primer. |

| Finally adding a colour

coat.

Plus a coat of

lacquer to help protect the base colour and help it stand out.

|

|

|

|

The next stage in the

re-build was to totally strip out the interior and all the roof head

lining, roof vinyl and front screen.

The

passengers door was removed and scrapped as the rot at the bottom of

it was too far gone for repair.

|

The

boot lid was also marked out for the rear spoiler and temporarily fitted to

check alignment.

The next stage of the

rebuild involved the fitting of a V8 engine and gearbox from a Rover

SD1

It is a tight fit. I will have to use a different radiator and

relocate it further forward in the bay.

Then I will have to manufacture engine mounts, a gearbox

cross-member and a prop shaft to suit the gearbox.

The

rear diff I will use, will be a 3.09 LSD from a 2.8 CAPRI .

|

|

|

|

I made up engine mounting brackets and

fitted a radiator from a Montego turbo diesel, which I later changed

to a Ford Sierra radiator from a 1.8 turbo diesel, due to it's

larger capacity. Now the engine is finally in place.

The 3.09

LSD diff is fitted along with the prop shaft. The front part

being Rover and the rear part Ford.

|

| The new door is fitted.

I have started to rub down the

body before restoring it to it's original colour Honda metallic

blue.

|

|

|

|

Here I have applied the first primer

coat and then rubbed down the Javelin with wet and dry paper to

check for any blemishes.

Another coat of primer is sprayed and the

procedure repeated. |

| The car was washed and dried.

I tac ragged the car before applying the base

coat. Honda metallic blue. |

|

|

The last coat is the laquer, which adds

a shine to the base coat.

Finally the car is brought home to continue with

the rebuild.

|

After this the next

stage will be to manufacture exhaust systems, re-build the engine bay wiring

loom and begin putting the rest of the car back together. Fit the cooling

and fuel systems so that the engine can be test run.

| I am almost there, but

still have lots of minor things to do though.

The exhaust headers have been a

nightmare.

Trying to find the head light bowls

for the original lights so far have eluded me. I have opted for the

alternative of twin round ones from the Capri . |

|

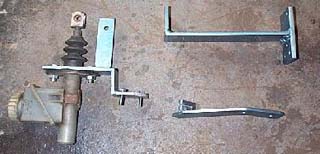

Another problem still to over come is the

clutch, trying to sort out the mechanism to operate it as space is very

limited.

| The clutch mechanism I found that would

suit is from a Volvo 740.

However I did have to design and make up the

brackets. The clutch works off it's own original cable. |

|

|

On the road again No.1 arrives at the

M.O.T. station. Will she pass?

After all that work she should. |

| The Javelin is virtually complete with

some minor items still to be completed. These don't affect the M.O.T. or

prevent the car from being used on the road.

No problems here.

The Javelin No.1 Passed with flying colours.

|

|

The Javelin is now taxed and is ready for some short test

runs, to sort out any teething problems. Now I can attend to the little jobs

that were not required for the M.O.T.

First the Hood

With such variable weather here in Scotland

the hood section was a priority.

| I was more than pleased, by the way

the hood turned out.

An excellent job David Thanks very much.

The price was very reasonable too. |

|

|

Details of Alex's Work &

Suppliers.

Exhaust Manifold Flanges purchased from Lolocost

Kit Car Spares.

Remote Oil Filter Kit purchased from Merlin

Motor Sport.

|

Rear Hood made by David

at

DSC. Covers. Unit D, Gilmerton Estate, East Fortune, Lothian.

Tel:- 01620-880-652 |

Exhaust Headers own make & design. Welded by

Mitsui Babcock.

Engine Mounts own make & design, cross between

Rover & Ford. Welded by Mitsui Babcock.

Rear Axle Cross Frame location kit own make &

design.

Lower Front Anti-Roll Bar Mounts 1" lower own

make & design.

O/S Targa Top lock/unlock mechanism own set up to

work similar to N/S.

Radiator Electric Cooling Fans from Ford Sierra

1.8 turbo diesel. Mounting brackets own make.

Recaro Front Seats from a Vauxhall Vectra SRi.

All Welding repairs, Bodywork, Mechanical and

Wiring all done by myself. |

Check out Alex's own website Here.

Javelin

Part 1 Javelin Part 2

Javelin Part 3

My thanks to Alex Sargent for his photographs and help, in compiling this page.

Also to Dave Tennant for finding the photograph at the top, after all

these years.

|

J

B

A |